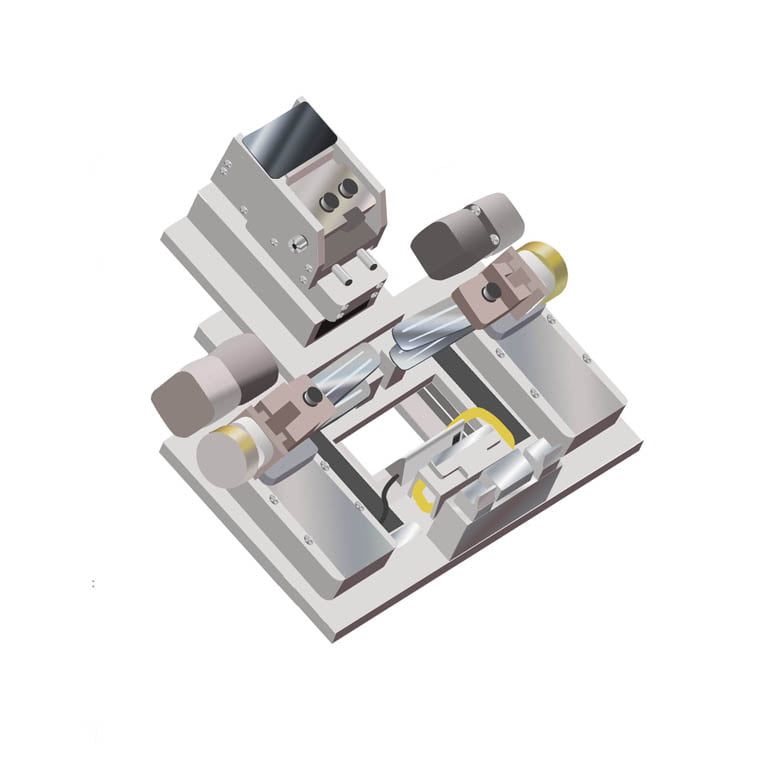

Assembly equipment for automobile parts

Delivery destination

Automobile industry

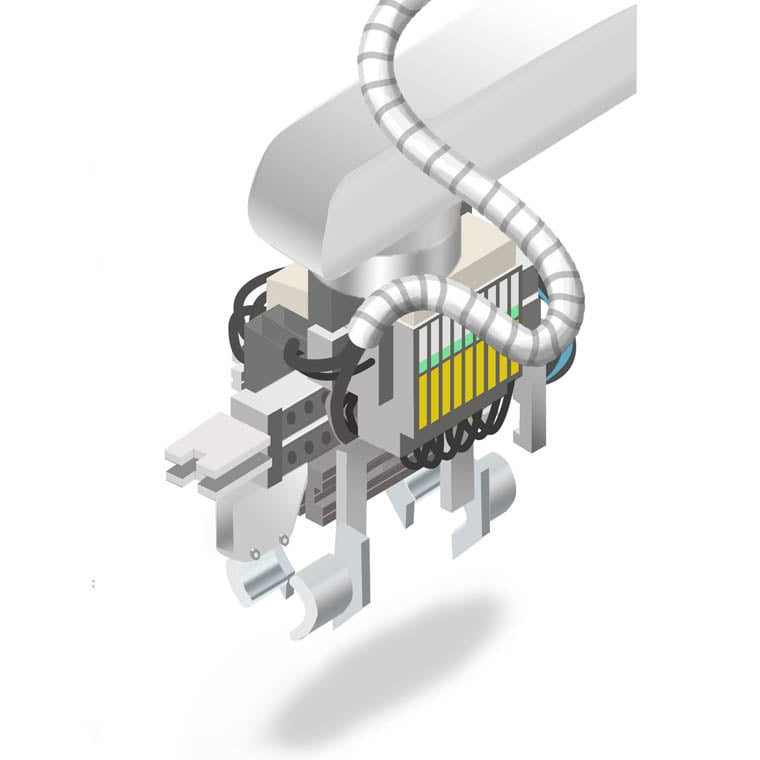

usefulness

Reduction in workers, reduction in labor

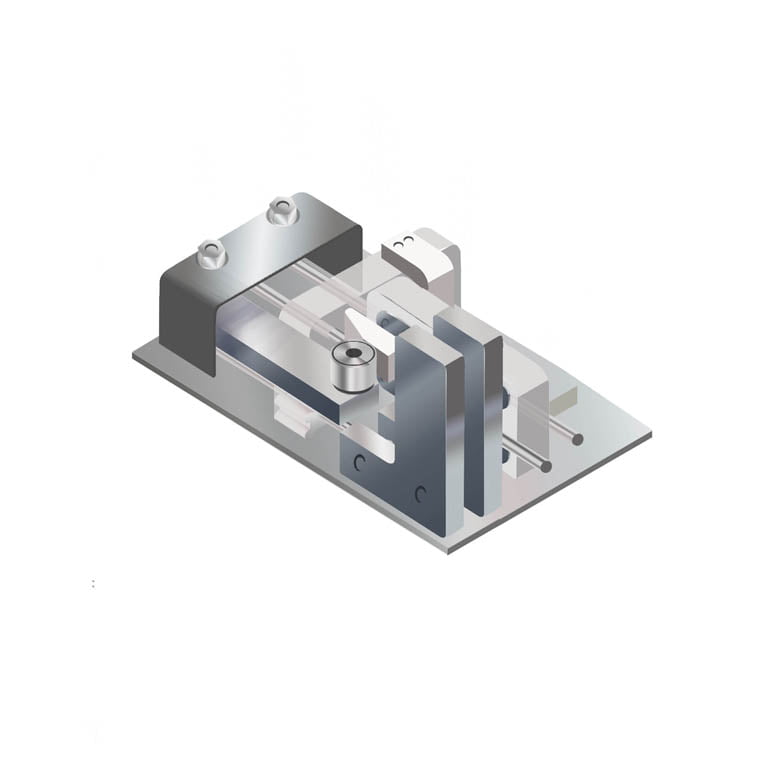

Equipment movement

- (1) Set the target product

- (2) Step on the foot switch

- (3) The target product is fixed

- (4) The target product is rolled

- (5) The guide comes down to the target product

- (6) The roll blade comes off

- (7) The worker folds along the guide

- (8) Stepping on the foot switch fixes the end of the fold

- (9) Stepping on the foot switch causes the guide to come off

- (10) The worker fixes a Z-fold at one location

- (11) Compress the target product

- (12) Remove the cover

- (13) Completion of product

Realized

Achieve reduction in labor through machinery. Reduce the unevenness in products that occurs when performed manually.

Technology used

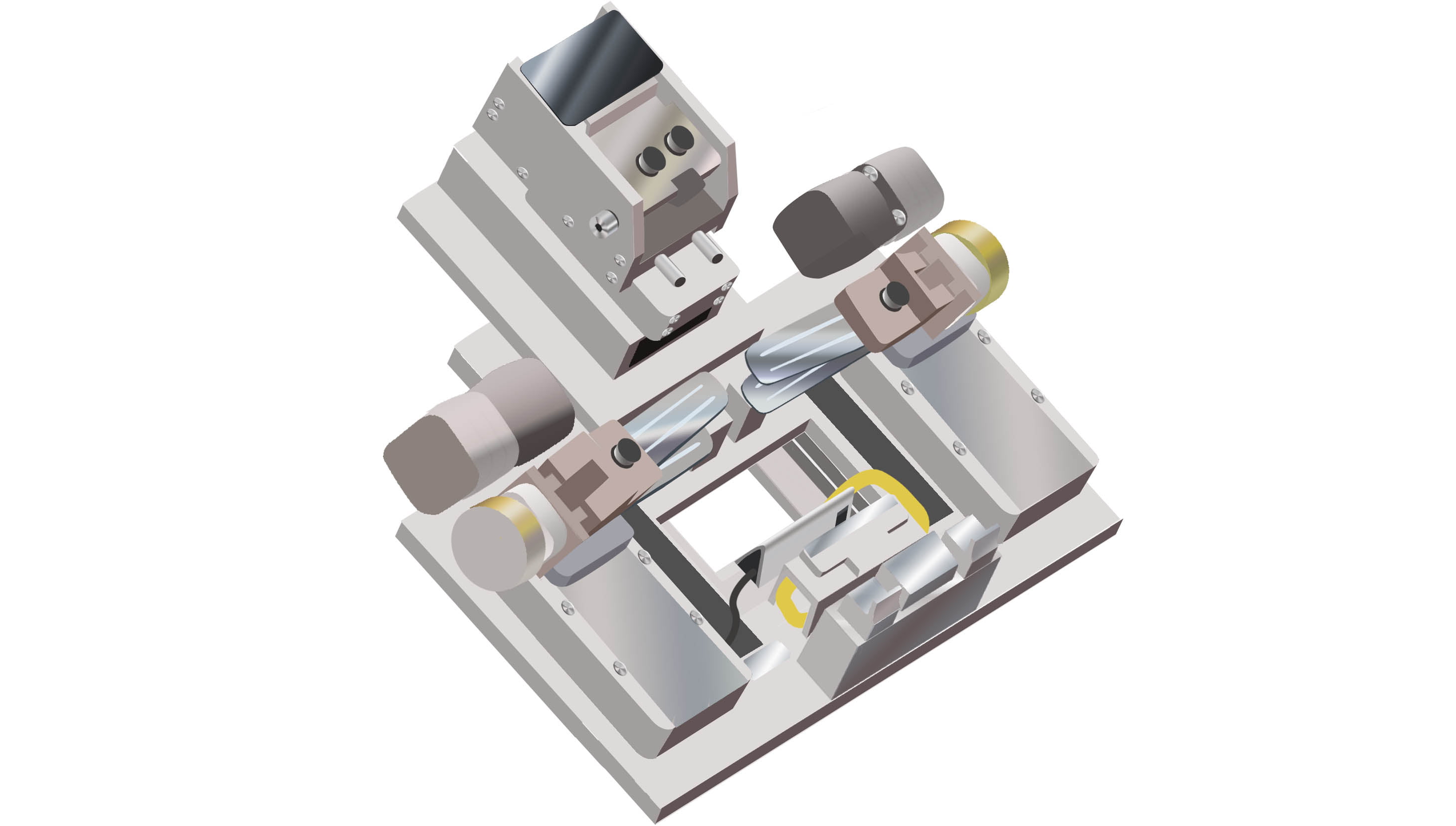

Z-fold

Make mountain folds and valley folds in the workpiece, and store. Use advanced technology to neatly fold workpieces.

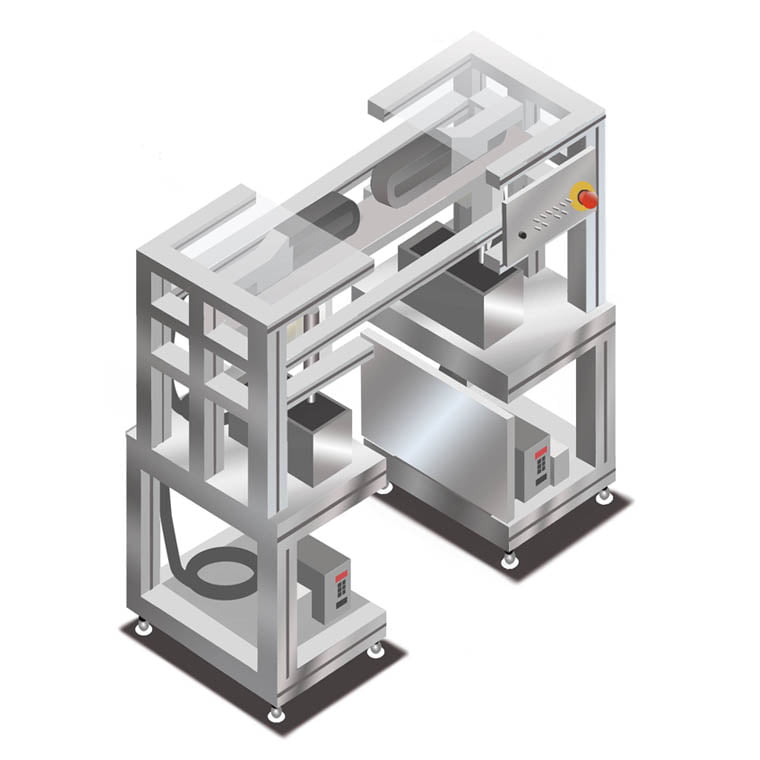

Automatic elevator

Adjust the height. Adjustment to the height of the worker is possible.

Human-friendly equipment

As joint work is performed by the equipment and people, the equipment is adjusted so that a hand caught in the equipment is not hurt.

Automatic speed adjustment

As folding occurs during rolling, the warp swells. The speed at which the robot descends and the rotation speed are adjusted to for slow winding, to prevent the workpiece from tearing when wound too quickly. With PLC, establish coordination between the rotation speed and machining speed.