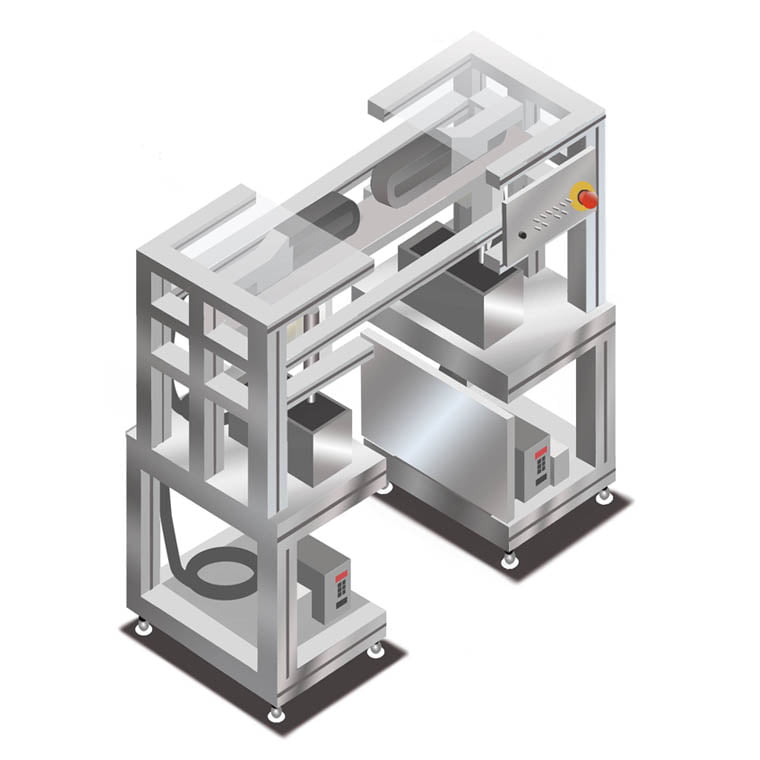

Thermal evaluation test equipment

Delivery destination

Electronic equipment industry

usefulness

Evaluation

Equipment movement

- (1) Set the product to be evaluated in the basket in the equipment

- (2) Enter the conditions in the touch panel

- (3) Press the “Start” button for automatic operation

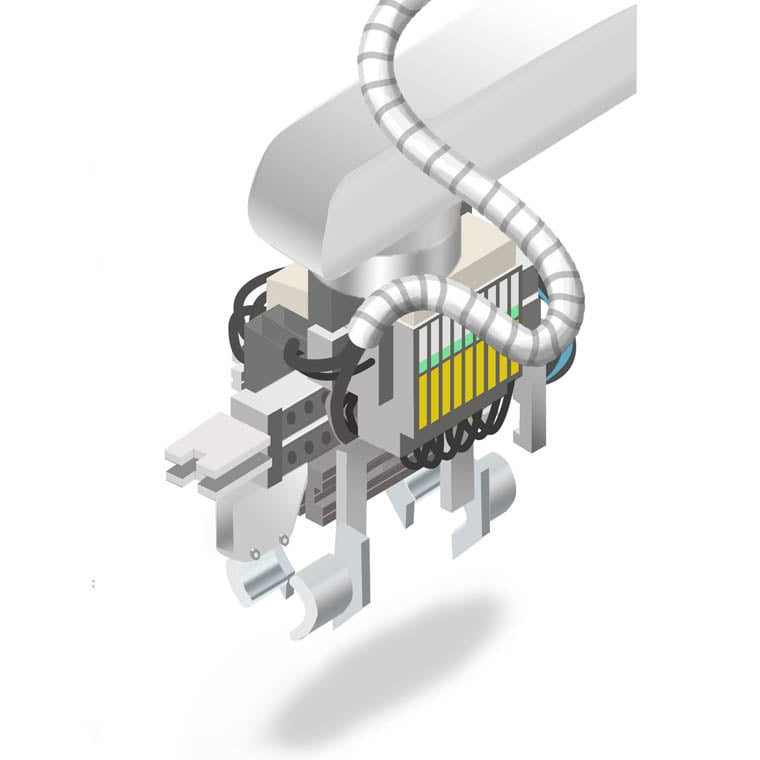

- (4) Evaluate cooling high temperatures, moving to the left and right according to conditions

- (5) Operate with liquid drip time taken into consideration

Realized

Mechanization/instrumentation of items for which equipment evaluation had been performed manually. By doing so, (1) achieve reduction in labor, and (2) reduce risk to people as oil is used

Technology used

Ducting

Ducting is performed, as evaporated steam filling the factory is not ideal in terms of sanitation. Consideration of sanitation aspects.

Full automation

Complete all processes with one button; after that, just perform removal

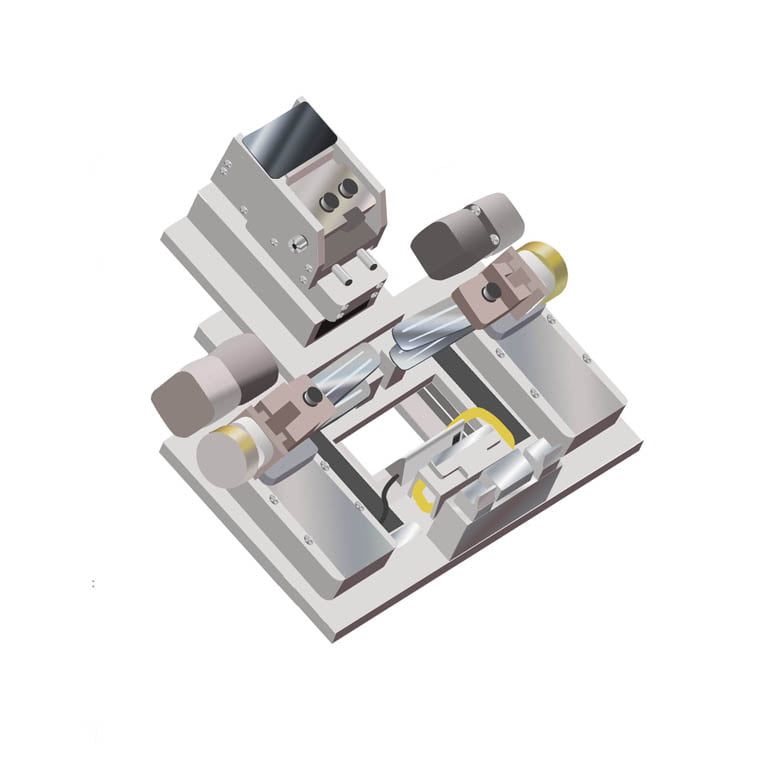

Thermal sensing with sensors

This enables stable evaluation

Safe design

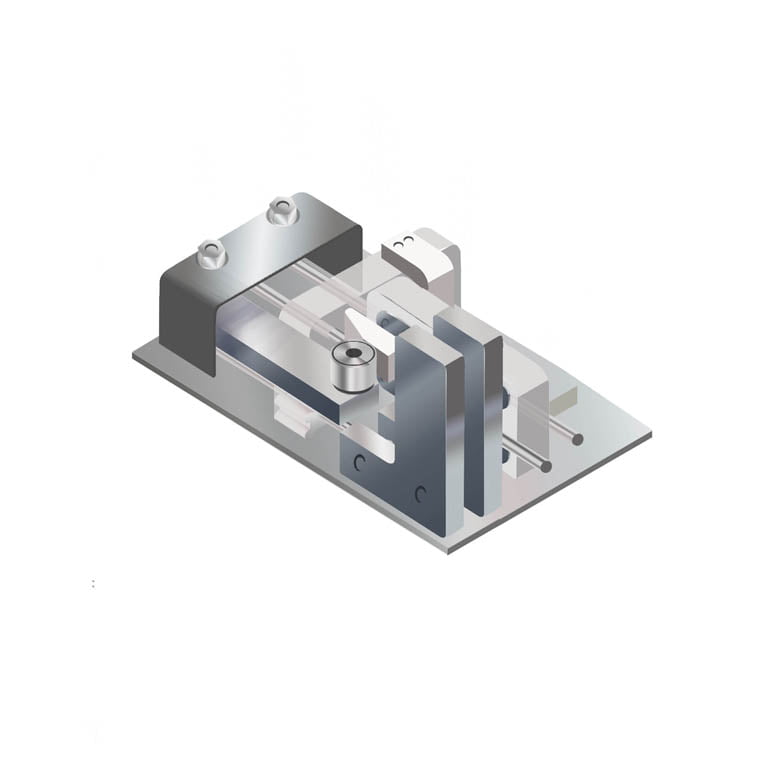

Design to prevent contamination through installation of a bottle to collect dripping under liquid leaks.

Easy operation

Operation status can be checked and simple operations can be performed using the touch panel.

Temperature adjustment

To equalize the temperature, the tank interior is agitated with a motor